High-Fidelity Modelling of Internally Geared Screw Machines

Advanced rotor profiling, high-performance simulations, and thermodynamic analysis of a novel screw compressor.

Rotor Profiling Techniques

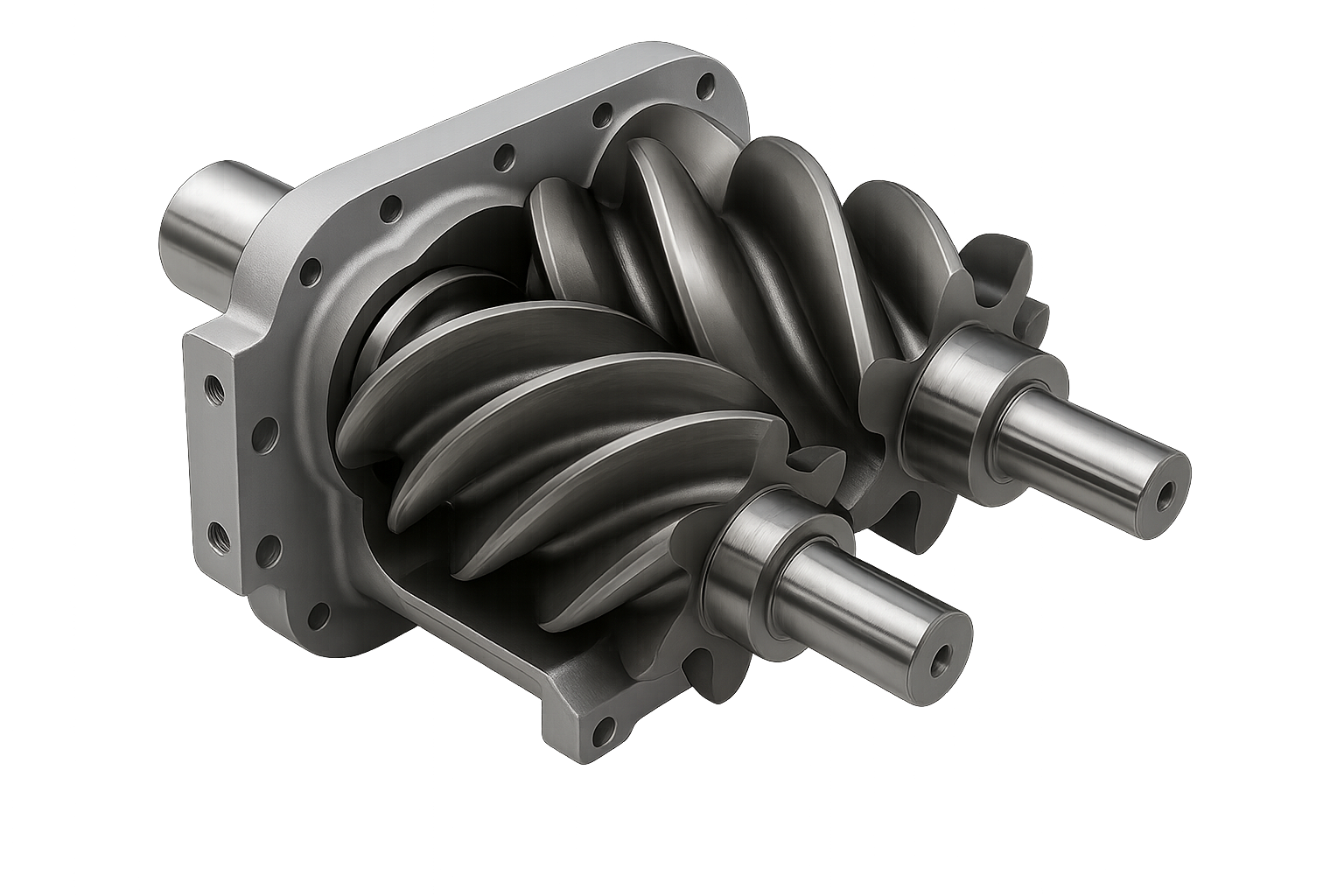

This PhD project investigates rotor profile generation techniques specific to Internally Geared Screw Machines (IGSM). The pin-generation method is implemented with circular pin geometry to ensure manufacturability and profile feasibility.

The rack method, a common approach in the conventional twin-screw compressors, is deeply analysed and adapted to the unique constraints of IGSM. This includes addressing conditions for continuous contact between the rotors and a minimum-zero area of a formed working chamber.

Deep neural networks are also evaluated for profile approximation and real-time generation to support industrial workflows with performance and generalisation capabilities.

High-Performance Geometry Framework

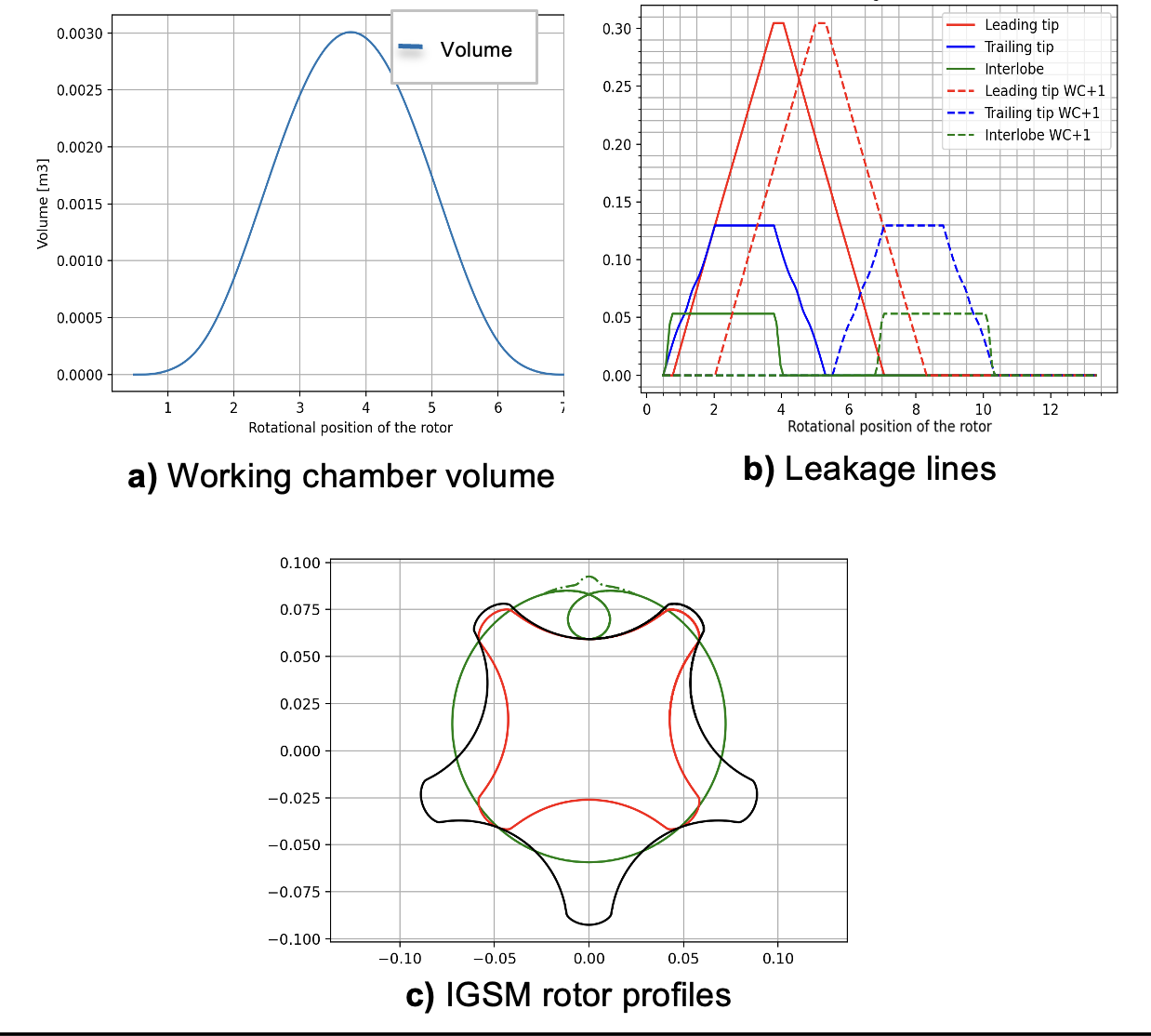

A dedicated geometry framework has been developed for IGSMs using both Python (initial investigation) and C++ (deployment). The framework efficiently computes chamber volume curves, leakage paths, and port areas.

The geometry module is fully integrated into the SCORG software, supporting mesh generation, thermodynamic evaluation, and CFD simulation pipelines.

Simulation and Optimisation

The SCORG chamber model is extended to work with IGSM-specific profiles, enabling simulation of the compression cycle. Pareto-based optimisation algorithms are applied to find design trade-offs across operating conditions.

Simulation results have been validated against high-fidelity CFD data, showing excellent agreement in air compression performance under industrial load profiles.